Our friends at Big River Industries assembled a tremendous project profile about the challenges and construction of the largest piece of eye-candy in the City of Nashville’s skyline: the Music City Center. At 4 acres of vegetated roof, the project is as large as it is bold. And it all grows on 1600 cubic yards of rooflite extensive mcl. We think Big River said it best, so the piece (available in pdf format HERE) in its entirety follows below.

***

There’s a meadow five stories above the busy city streets of Nashville complete with green grass and rolling hills. This green space in the sky is actually the roof of a new convention center nearing completion in the Music City.

rooflite greenroof media installation at the Nashville Music City Center

Ordinarily, rains pouring over the massive 1.2 million square foot building would drain into the city’s storm water system. But rather than tax the already strained system, some of which dates back to the 1880’s, most of the storm water landing on the new Music City Center will be retained by its specially designed roof.

This downtown development is part of the city’s green infrastructure program created to manage Nashville’s urban storm water challenges.

The building boasts a 175,000 square foot green roof containing rooflite®, a certified green roof media manufactured by Skyland USA. “Storm water management is a huge problem and that’s why there’s a push for more green roofs,” says Skyland USA’s Managing Director Joe DiNorscia. “They allow 60 to 80% of rainwater to stay on a roof to be absorbed by the plants or evaporated. What’s left comes down slower and that gives the sewer system a chance to better handle the runoff,” he says.

In the case of the Nashville project, designers specified a green roof media that had to be extra light and work in a shallow installation. Skyland’s rooflite® Extensive MCL product was a good fit for the project. “Our technical director, Peter Philippi, worked closely with Garick, one of our licensed rooflite blenders, to slightly tweak our blend to meet this project’s strict design specifications,” DiNorscia says.

Sedum Mats installed over rooflite Green Roof Soil

The Music City Center is working to achieve LEED® silver designation and the green roof is a prominent part of the effort. Developers were able to obtain points for sustainable site, water efficiency, and the use of regional materials. In the case of the engineered soil used in the roof, raw materials were sourced from central Alabama and middle Tennessee; well within LEED’s 500-mile radius requirement.

Garick manufactured all of the green roof media used for the massive convention center. “We’ve been working with Garick since our very beginning,” says DiNorscia. “We knew they were the exclusive distributor of HydRocks™ manufactured by Big River Industries and we wanted that calcined clay to be a key component of our product. We use a proprietary blend of the material made exclusively for us by Big River.”

Skyland works closely with a number of blenders like Garick nationwide to ensure their product has a consistent quality. “We seek out raw components from a particular region that are cost competitive in the marketplace. Most of the green roof projects in the East rely on HydRocks,” he says.

DiNorscia says successful green roof media has a number of specific requirements that on the surface, sound conflicted. “The product is really a contradiction in functionality,” he says. “On the one hand, it has to absorb as much water as it can. On the other, once it reaches that maximum absorption, the excess water must be able to drain off quickly.”

Green roof media not only has to both retain and drain water, it also has to keep these properties for a very long time. “Structural stability is a key factor for the long-term success of any green roof. The media has to keep its structure and work properly for the life of the roof.”

To support plant growth, the product must also have the proper nutrients, pH, and salinity levels. That’s a fact DiNorscia learned early on. For the last 15 years, he’s also served as general manager of Laurel Valley Soils, a maker of customized soil blends in Southeastern Pennsylvania.

“One of our very first requests for green roof media came to us about 10 or 12 years ago. A local nursery client, Ed Snodgrass of Green Roof Plants, wanted us to create a soil blend they could use for growing plants specifically for green roofs. We didn’t know what to put in it,” he says. “There was not a lot of information out there. After a lot of testing we finally came up with a blend that worked.”

For the next four years, DiNorscia watched as the green roof industry grew in the U.S. He also saw the pitfalls of the young industry.

“In the early days, most specifications for green roofs were custom written for a particular installation,” he says. “Coming up with those specs were costly and painstaking. That differed from what was being done in Europe, specifically in Germany, which had been doing green roofs since the 70’s. Over time, and by trial and error, the Germans developed blends for green roof media that were more or less standardized. That’s a concept we mimic today.”

In a partnership with a German group, Skyland USA was formed and the rooflite® brand was created. “Laurel Valley Soils had the expertise in manufacturing, while our German counterparts had the expertise to develop those standardized blends,” he notes.

With the country’s different climates and raw materials, DiNorscia says members of the green roof industry were skeptical standardized blends would work. “At first, we faced a lot of push back from the designers and green roof installers. They were used to working with at-ground landscaping so they wanted to duplicate their soil designs on green roofs. It just didn’t work.”

But that resistance has faded. Since their small nursery project in 2002, Skyland USA has supplied engineered soil media for over 700 green roofs that span the entire continental United States. That extensive project list provides proof of their product’s performance and unmatched experience in everything from specification to logistics. Getting the product to the job site and up on the roof is a critical aspect of every green roof project. In the case of Music City Center, that meant material delivery in a busy urban environment and placement five stories high.

LSS installs rooflite green roof soil with a pneumatic blower

“Logistics is a real key component,” says DiNorscia. “One client calls it a material handling puzzle. We like to say that working as a team, we can solve that puzzle for our customer.”

He turns to Scott McGaughy and Landscape Support Services as an example. “Our rooflite material was placed using their pneumatic blower trucks. We work closely with their installation team and they find our material easy to work with,” he says.

Since the green roof media specified for this project is very shallow, less than three inches deep, that meant pre-vegetated mats would be used for the rooftop plants. The rooflite extensive mcl product is specifically designed for such installations. There has to be full time irrigation but that won’t be a problem for this project. Another sustainable feature of Music City Center is a water reclamation tank so that excess rain water can be used for site irrigation and flushing the center’s toilets.

“This project is great example of what a total team concept can accomplish,” says DiNorscia. “From our expertise in standardized blends, to Garick’s manufacturing experience, Big River’s extremely lightweight HydRocks material, and the logistical and placement know-how of Landscape Support Services I’m certain this project will be a success for the developers and the city of Nashville.”

***

Big River Industries manufactures HydRocks® Calcined Clay

Garick is the exclusive distributor of HydRocks, a licensed manufacturer of rooflite products, and a member of the rooflite Regional Production Network.

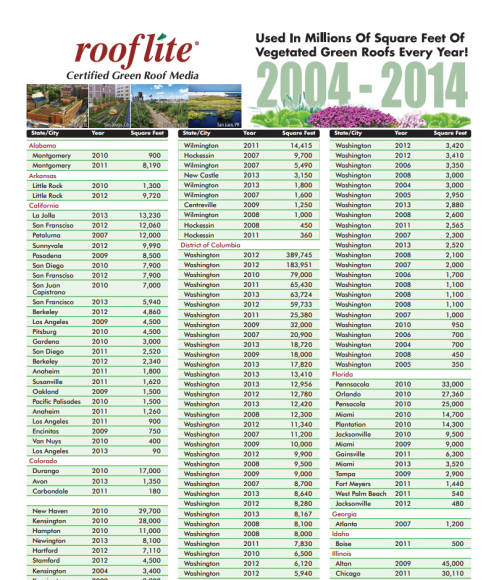

Skyland USA is the creator of rooflite certified green roof media products, North America’s leading green roof soil. rooflite® certified green roof media products have been installed on over 700 projects and 6 Million square feet of thriving green roofs across the North American continent, including convention centers from north to south, with a track record unmatched.

Grow On Us™: www.rooflitesoil.com

Read Full Post »